Think getting the cheapest shipping rates is an easy/obvious decision? Think again.

That low-cost carrier contract might look like a win at first—until things start to go wrong. Suddenly, there are delays, complaints, and disruptions popping up out of nowhere, leaving you wondering where it all went wrong.

Sound familiar? Watch this short video below—because the real cost of shipping is often hidden in what you don’t see upfront.

It’s time to look beyond the price tag. Let’s uncover the hidden factors affecting your bottom line and how you can turn shipping into a smarter, more profitable part of your business.

Table of contents

- The hidden costs of shipping

- What is the Total Cost of Shipping (TCS)?

- Breaking down the Total Cost of Shipping

- 4 Strategies to take control of the Total Cost of Shipping

- Real-world insights on the Total Cost of Shipping

- Comparing scenarios: Cheap rates vs. Total Cost of Shipping

- Rethink your online business’s shipping game

The hidden costs of shipping

For many online retailers, the math seems simple: choose the cheapest carrier and keep expenses low. But what if those budget-friendly rates come with hidden costs that chip away at your profits?

The reality behind cheap rates

Relying on low-cost carriers often brings unexpected challenges, like:

- Unreliable deliveries: Delays, missed SLAs (service-level agreements), and unresolved customer complaints disrupt your workflow and harm your reputation.

- Customer support overload: Delivery hiccups mean more WISMO (“Where Is My Order?”) inquiries, draining your resources and stressing your team.

- Sneaky invoice errors: Nearly 20% of carrier invoices contain errors, quietly eating into your budget with overcharges.

- Operational risks: Relying on a single carrier leaves you vulnerable to service disruptions, price hikes, or capacity shortages during peak seasons.

The ripple effect on your business

These hidden costs don’t just dent your bottom line—they impact your entire operation:

- Damaged customer trust: A bad delivery experience frustrates shoppers and erodes loyalty.

- Higher expenses over time: Savings on rates are quickly overshadowed by inefficiencies and extra costs.

- Missed growth opportunities: Without an optimized shipping strategy, scaling your business or improving customer experiences becomes a challenge.

Focusing on cheap shipping might feel like the safe choice, but it’s often a costly gamble. Recognizing these pitfalls is the first step to building a smarter, more resilient strategy—one that saves more than just pennies.

What is the Total Cost of Shipping (TCS)?

The Total Cost of Shipping (TCS) is a smarter way to evaluate your shipping expenses. Instead of just comparing base rates, TCS looks at every factor that impacts your costs, efficiency, and customer satisfaction.

At its heart, TCS includes:

- Base shipping rates: The cost of getting parcels from point A to point B.

- Carrier performance: Metrics like SLA compliance, delivery success rates, and exceptions that influence costs and customer trust.

- Customer service costs: Expenses from handling WISMO (“Where Is My Order?”) queries and solving delivery issues.

- Invoice accuracy: Hidden overcharges and billing errors that inflate your expenses.

Operational risks: Dependence on a single carrier, which leaves you exposed to disruptions, rate hikes, or capacity shortages.

Why the Total Cost of Shipping matters

Taking a TCS approach gives you a full picture of your shipping operations and unlocks valuable benefits:

Transparency: Gain a clear understanding of all shipping costs, both visible and hidden.

Spot inefficiencies: Identify costly issues, such as delays, high support costs, and routes that can be optimized.

Smarter decisions: Use accurate shipping data to optimize carriers, streamline processes, negotiate better rates, and reduce unnecessary costs.

Breaking down the Total Cost of Shipping

The Total Cost of Shipping (TCS) goes far beyond base rates. It’s shaped by hidden factors that can quietly drain profitability. Let’s take a closer look at the key contributors and how they can drive inefficiencies.

1. Carrier performance

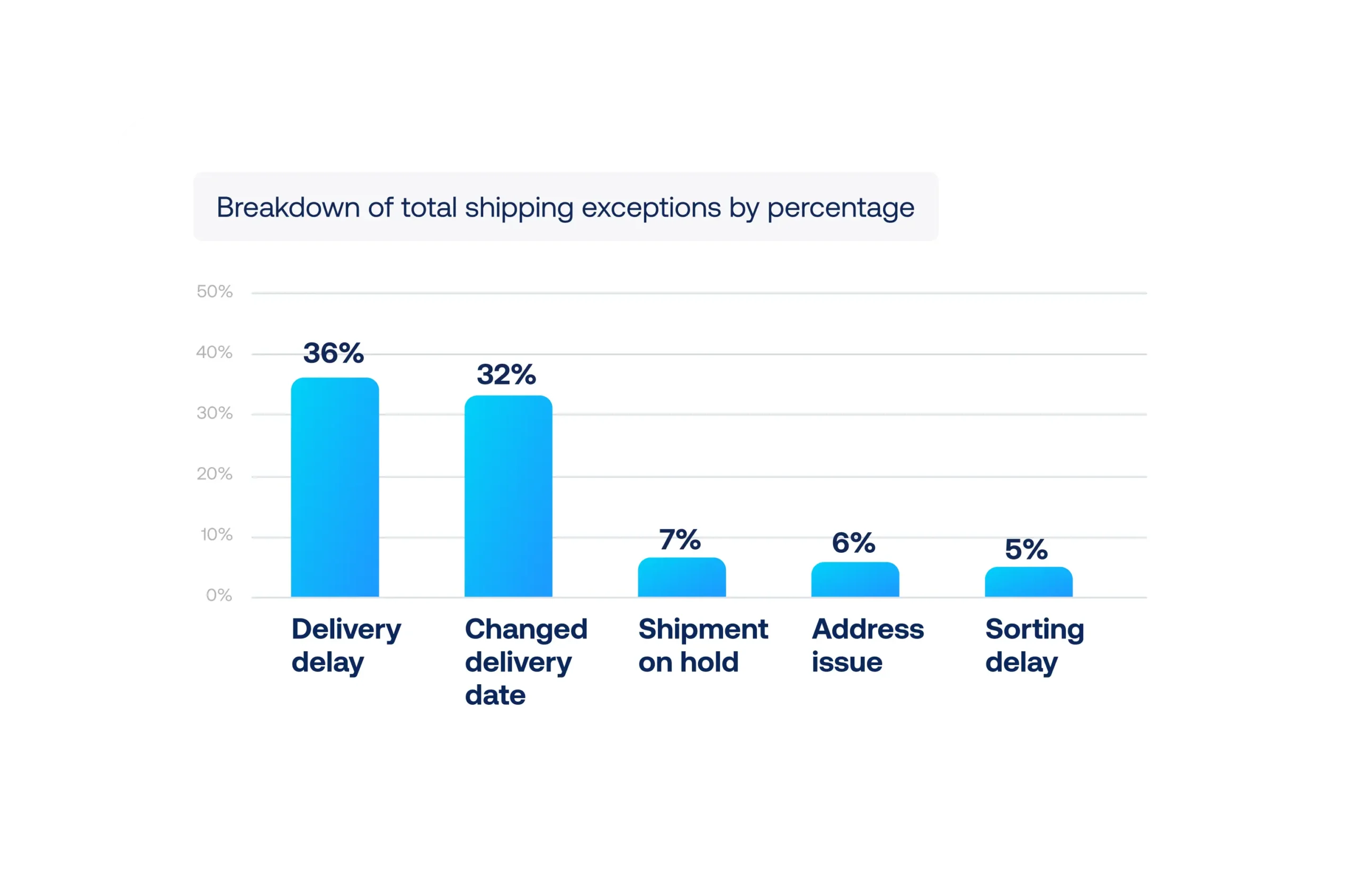

Carrier reliability is at the core of your shipping operations—but it’s often sacrificed in the quest for lower costs. Issues like delivery delays, changed delivery dates, and address problems can frustrate customers and disrupt operations. For instance, delivery delays alone account for 35.94% of all exceptions, making them the most common—and the most damaging—issue.

When exceptions occur, the ripple effects are hard to ignore: customer inquiries pile up, manual tracking eats into your team’s time, and reshipments chip away at your margins. These aren’t just isolated issues—they create a chain reaction that increases costs across your entire business.

Unreliable carriers also erode customer trust. A late delivery isn’t just an inconvenience; it impacts how customers perceive your brand. Without regularly monitoring SLA compliance and delivery success rates, it’s tough to identify weak spots, leaving your business vulnerable to dissatisfied customers.

2. Customer support costs

2. Customer support costs

Delivery-related inquiries, often called WISMO (“Where Is My Order?”), are a hidden drain on e-commerce businesses. On average, 2-8% of shipments lead to these inquiries, with each ticket costing around €11 to resolve. But the impact isn’t just financial—your customer service team gets stretched thin, leaving less time for other vital tasks.

At scale, the numbers add up fast. Imagine you ship 50 000 parcels a month, and 4% of them result in inquiries—that’s 2000 tickets and over €7000 in monthly support costs. The surprising part? Many of these inquiries stem from preventable issues, like poorly communicated delivery updates. The result is frustration for your customers and extra pressure on your team.

WISMO is a key factor that influences efficiency, customer satisfaction, and ultimately, your bottom line.

3. Invoice accuracy

Carrier invoices might look simple, but they’re often anything but accurate. In fact, studies show that up to 20% of invoices contain errors, with our platform data showing that around 1.5% of total billed amounts are inaccurate. While that might not sound like much, those overcharges can quickly snowball when you’re shipping at scale, quietly draining your profits.

These mistakes can come from anywhere—misapplied surcharges, incorrect dimensional weight calculations, or simple human error. The sheer volume of invoices makes it nearly impossible to catch every discrepancy manually. For growing businesses, these unchecked errors can create a steady leak in profitability.

The impact doesn’t stop at your budget. Invoice inaccuracies can strain your relationships with carriers and make it harder to maintain predictable shipping costs.

4. Operational risks

Relying on a single carrier might seem like a convenient choice, but it’s a risky one. A service outage, sudden price hike, or capacity crunch can bring your shipping operations to a standstill, leaving you scrambling to meet customer expectations. This kind of dependency doesn’t just increase the chances of delays—it also weakens your position when it’s time to negotiate contracts.

Over-reliance on one carrier also limits your flexibility. When carriers change their pricing or service levels, businesses without a diverse carrier mix are left stuck, unable to pivot to better options. This lack of adaptability exposes you to cost spikes and operational chaos—especially during peak seasons or unexpected disruptions.

4 Strategies to take control of the Total Cost of Shipping

Reducing your Total Cost of Shipping (TCS) takes a proactive, data-driven approach. Here’s how to stay ahead:

1. Proactive management

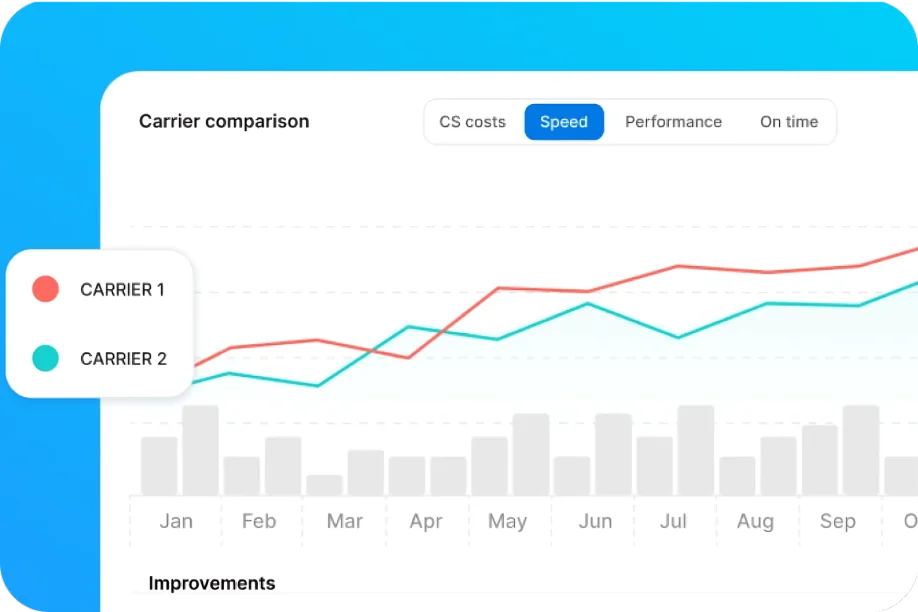

Taking charge of your shipping operations starts with knowing how your carriers are performing. Regularly analyzing metrics like SLA compliance, on-time delivery rates, exception frequencies, and transit times helps you uncover inefficiencies that quietly drive up costs.

For example, carriers with frequent delays or SLA breaches increase WISMO inquiries and drive up support costs. Addressing these issues positively impacts both customer satisfaction and profitability.

Performance tracking also gives you an edge during contract negotiations. With your own data at hand, you can:

- Call out underperformance: Back up your points with clear evidence of delays or SLA failures.

- Compare options: Benchmark your carriers against competitors to find the best fit.

- Negotiate smarter: Push for better terms, like reduced surcharges or priority handling.

Transparency is the game-changer here. Businesses that consistently monitor carrier performance can hold carriers accountable, spot trends (like seasonal delivery issues), and make informed, data-driven decisions that keep costs in check.

Learn how to retrieve shipment data from carriers in our dedicated article!

“We feel more in control. Carrier performance data helps us better understand our delivery process. It makes us look differently at carrier selection and strengthens our position when talking to carriers, allowing us to negotiate better terms.”

— Alex Formicola, Rosefield

2. Automate your shipping operations

Automation can transform your shipping processes by streamlining operations, reducing inefficiencies, and saving valuable resources. It’s a practical way to tackle common logistical challenges while enabling your team to focus on higher priorities.

A key area where automation shines is in proactive communication. Automated tracking updates can reduce WISMO (“Where Is My Order?”) inquiries by up to 45%, helping to lighten the workload on customer support teams while keeping customers informed and reassured.

Automation is also invaluable when dealing with delivery exceptions. When issues like delays, missed scans, or address problems occur, automated systems can:

Identify exceptions as they happen.

Notify customers immediately with clear updates.

Trigger workflows to resolve problems, such as re-routing shipments or contacting carriers.

Advanced shipping analytics tools take this further by using historical and real-time data to predict potential delivery delays. This insight allows for proactive measures that prevent disruptions and maintain a smoother delivery experience.

By enhancing visibility into the last mile of delivery, automation helps address problems quickly and reduces the risk of escalation into costly support cases. Internally, automating tasks like label creation, carrier selection, and invoice reconciliation helps minimize errors and save time, simplifying workflows for your team.

3. Diversify your carrier portfolio

Sticking with a single carrier might feel like the easy choice, but it’s a risky one. Carrier outages, sudden price hikes, or poor performance can throw your shipping operations into chaos, leaving you scrambling for alternatives. Diversifying your carrier portfolio is a smarter, more resilient approach that protects your logistics and optimizes costs.

By partnering with multiple carriers, you gain the flexibility to:

- Adapt to disruptions: When one carrier faces delays, outages, or strikes, you can shift shipments to another without missing a beat.

- Control pricing risks: With multiple options, you’re not locked into a single pricing structure. You can negotiate better rates or switch to more affordable carriers when needed.

- Match carriers to specific needs: Some carriers excel in certain regions, delivery speeds, or handling specific goods. Diversification lets you choose the best fit for every shipment.

Exploring new carriers can uncover surprising savings. For example, businesses that compare performance and rates often find cost-cutting opportunities.

4. Keep tabs with regular audits

Shipping invoices can be full of surprises—like surcharges, adjustments, and errors that quietly eat into your budget. That’s why regular audits are a smart way to stay on top of things. They can help you:

-

-

- Spot hidden shipping overcharges: Catch errors in billed amounts, surcharges, and adjustments that don’t match your agreements.

- Reclaim lost funds: Identify errors and claim refunds for charges you shouldn’t have paid.

- Strengthen your contracts: Use what you learn from audits to negotiate fairer rates with carriers and ensure more accurate billing.

-

If the idea of manually sifting through invoices feels overwhelming, don’t worry—parcel audit software can help make the process faster and easier.

Parcel audits not only improve your profitability but also provide a perfect opportunity to take a closer look at your contracts. You might discover terms that no longer make sense for your business or services you don’t actually need. Renegotiating these can lead to noticeable cost savings.

By keeping an eye on your shipping invoices, you’re not just protecting your budget—you’re gaining insights that can help you refine your carrier strategy, eliminate inefficiencies, and ensure every euro you spend is working hard for your business.

Real-world insights on the Total Cost of Shipping

The Total Cost of Shipping (TCS) delivers real results. Here are some success stories from businesses that embraced TCS to improve their logistics and cut costs:

Reducing WISMO inquiries

By introducing proactive delivery updates with real-time notifications, World Wide Lighting reduced WISMO (“Where Is My Order?”) inquiries by 35%. This not only cut customer support costs but also enhanced customer satisfaction.

“Over the last year, we have seen a 35% decrease in ‘Where is my order?’ questions, while 9 out of 10 customers say they appreciate proactive delivery communication.”

— Carel van Boetzelaer, CEO of World Wide Lighting

Invoice audits and cost savings

Invoice audits uncover an average of 1.5% in overcharges—small percentages that make a big impact when scaled. For XXL Nutrition, shipping over 1.3 million packages annually, this meant significant cost savings. By using shipping data tools, they detected errors, optimized operations, and gained valuable insights for negotiating with carriers and addressing performance issues early.

“With tools to overlay shipping data on the invoice, we’ve removed incorrect charges, saved time and money, and gained better insight into carrier performance to raise the alarm in time.”

— René van der Zel, founder of XXL Nutrition

A/B testing new carriers

Switching carriers can feel like a gamble, but data tells the real story. After A/B testing two carriers for a few months, an e-commerce company that specializes in lighting products and operates in 15 countries uncovered a game-changing opportunity: a new carrier that reduced shipping costs by 27% without compromising delivery expectations. Here’s how they did it:

- Compared current carrier performance with alternatives.

- Shifted part of their volume to the new carrier.

- Measured results over a few months.

- Confirmed savings and reliability before fully switching.

Comparing scenarios: Cheap rates vs. Total Cost of Shipping

When it comes to shipping strategies, focusing solely on base rates can be misleading. The smarter approach? Evaluate the Total Cost of Shipping (TCS) to see the bigger picture. Let’s break down how these two approaches stack up:

| Factor | Scenario 1: Cheapest carrier (€4.90/parcel) | Scenario 2: Managing TCS (€5.10/parcel) |

| Base rate | €4.90 | €5.10 |

| Delivery delays | Frequent delays, frustrating customers | Reduced delays through proactive management |

| WISMO inquiries | High (€11/call), driving up support costs | Fewer inquiries due to proactive updates |

| Invoice errors | ~5-6% contain overcharges | Regular audits eliminate overcharges |

| Total Cost of Shipping | €5.60/parcel | €5.15/parcel |

Key takeaway

While Scenario 1 might look cheaper on the surface, hidden costs like delivery delays, rising support expenses, and invoice errors quickly add up. On the other hand, Scenario 2 shows that taking control of the Total Cost of Shipping (TCS)—through proactive communication, regular audits, and tackling inefficiencies—results in lower overall costs and happier customers.

By shifting your focus from base rates to TCS, you can uncover meaningful savings and build a stronger, more reliable shipping strategy that sets your business up for long-term success.

Rethink your online business’s shipping game

Shipping costs aren’t always what they seem. Sure, the base rates catch your eye, but what about the hidden costs? The delivery delays that frustrate customers. The flood of WISMO (“Where Is My Order?”) inquiries. Those small invoice errors quietly eating into your margins. If any of this sounds familiar, it might be time to rethink your system.

When was the last time you took a hard look at how these issues impact your bottom line? Delivery exceptions? Overcharges? Lost customer trust? If it’s been a while—or never—it’s time to dig deeper.

Here’s the good news: these aren’t unsolvable problems. Gaining control over your total cost of shipping can help you uncover inefficiencies, streamline your process, and turn shipping headaches into opportunities.

Need help getting started? Check out our Shipping Intelligence solution. It’s designed to give you insights into your shipping operations and help you save where it matters most. Or, if you’re still exploring, check out our guide to the best logistics software tools to compare your options.

Remember, shipping doesn’t have to be a problem—it can be your advantage. Start making changes today. Your customers, your business, and your future self will thank you.

2. Customer support costs

2. Customer support costs